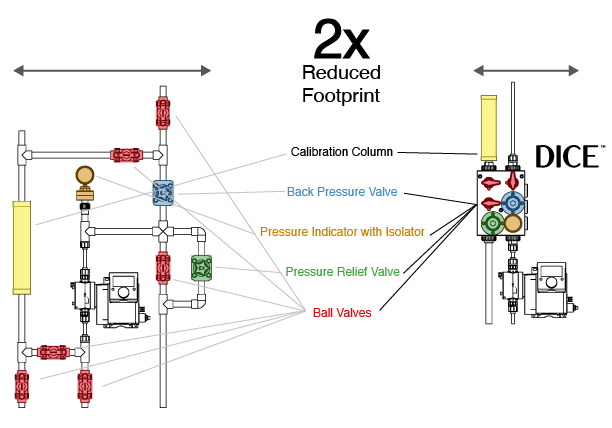

DICE Technology: simple, compact, all-in-one solution for chemical dosing

The DICE dosing modules integrate all the necessary discharge components required for a typical chemical dosing system.

The block type design allows for a rigid, compact and reliable product. The significantly reduced number of connections is a major benefit as it greatly decreases the leakage potential.

The modules allow for better precision and protection in the dosing system. They also feature great quality due to their machined fabrication and an extremely small required footprint.

Municipal & Industrial Applications

Solving Chemical Leaks

A leak-proof chemical dosing system allows for a reliable and efficient process, providing a better environment for employees.

Simplifying Dosing Systems

A simple system makes it easier to troubleshoot problems in the event of an emergency as well as simplifying the work of the operators.

Reducing Maintenance Costs & Time

A leak-proof chemical dosing system allows for a reliable and efficient process, providing a better environment for employees.

Institutional & Commercial Applications

Enhancing Reliability & Precision

Chemical dosing systems must operate repeatably without losing prime, which increases efficiency.

Eliminating Risks of Overpressure

Health and safety: All chemical dosing systems should have a pressure relief valve to avoid risks of overpressure and failure, exposing employees to chemicals.

Optimizing System Operation

A system validated within seconds during a routine inspection or after a chemical drum replacement improves efficiency.

Dice DS for Suction Lift Applications

- Adjustable Back Pressure Valve

- Adjustable Pressure Relief Valve

- Pressure Gauge with Isolator

- Bleed Valve

- Ball Valves for Outlets, Calibration Column and Drainage

Auxiliary Ports

- Pulsation Dampener

- Washing Port

- Transport/Dilution Water

- Secondary Pump

Dice DM for Flooded Suction Applications

- Adjustable Back Pressure Valve

- Adjustable Pressure Relief Valve

- Pressure Gauge with Isolator

- Bleed Valve

- Ball Valves for Outlets, Calibration Column and Drainage

Auxiliary Ports

- Pulsation Dampener

- Washing Port

- Transport/Dilution Water

- Secondary Pump

Other standard materials:

Ball valve handle | ABS plastic

Ball valve seat | Virgin PTFE

Bolts, nuts, washers, set screws | 18-8 stainless steel

Note | other materials can be supplied upon request

The Supplyline team is here to help!